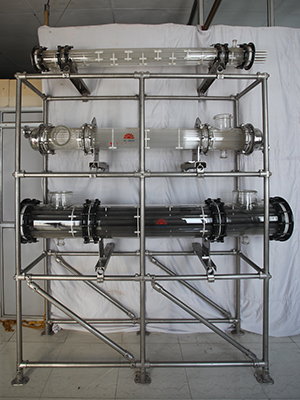

Tantalum Heat Exchanger

Tantalum Heat Exchanger

Tantalum Heat Exchanger : For heating with saturated steam, metal heaters have a number of advantages:

- High safety in operation.

- Small exchange areas owing to high thermal conductivity.

- No restriction on the steam pressure, since the design can be matched to the duty.

Typical metals used for corrosion-resistant heat exchangers are:

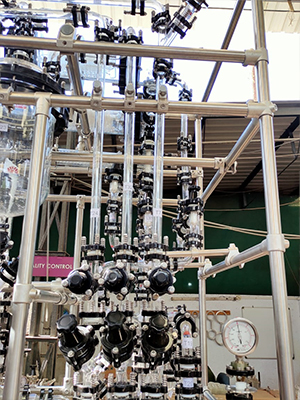

The construction, especially of the larger units incorporates all the features required for operational safety :-

- High-alloy stainless steels.

- Hastelloy.

- Titanium.

- Tantalum.

Tantalum in particular has the advantage that its corrosion characteristics largely correspond to those of borosilicate glass and is therefore suitable for universal use. Tantalum heat exchangers may be Bayonet or Shell and Tube type.

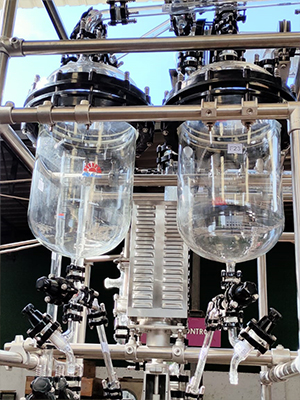

The components which readily fit into glass equipment:

- Basket heaters.

- Coil heaters.

- Single-tube bayonet heaters.

- Multiple-tube bayonet heaters.

Evaporator and Thermo Syphon Evaporatorss are frequently used for evaporation and distillation. Multiple-tube bayonet heaters, which are included in the standard range with exchange areas ranging from 0.1 to 10 m2, are particularly suitable for this purpose. Due to their construction, the heat transfer coefficients achieved in practice can be very high :

- K= 1500 – 2500 W/m2K.

Tantalum heat exchanger consists of Tantalum tubes with Carbon Steel Shell. The construction consists of fully welded metal design. Tantalum is immune to thermal and mechanical shock. The tantalum heat exchangers have a life expectancy of about 7 to 8 years. A tantalum heat exchanger utilizes a fully welded metal design that has no gaskets to leak. The tantalum heat exchangers are usually subject to Dye Penetration for surface cracks detection, Hydro testing and in certain case Helium leak testing to check the equipment leakage. The tantalum heat exchangers will require cleaning after every 2 to 3 years.

Tantalum is highly corrosion-resistant to :-

- Sulfuric acid.

- Hydrochloric acid.

- Bromines and their mixtures.

- Strong organic acids.

- Nitric acid.

- Phosphoric acid.