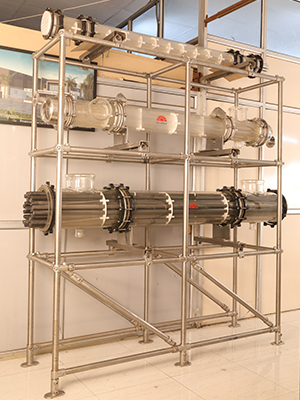

Glass Shell & Tube Heat Exchangers

Glass Shell & Tube Heat Exchangers

Glass Heat Exchangers

General Description:-

Glass Shell & Tube Heat Exchangers – Heat must be transferred between two fluids in many different processes in the chemical, nuclear and pharmaceutical industries. Therefore heat exchangers are the crucial components in many chemical process plants.

Types of Construction

The requirement for larger exchange areas in conjunction with a compact construction has been met by development of shell and tube heat exchangers. Whether installed as a single unit or a part of complete installation shell and tube heat exchangers offer significant advantages:-

- Corrosion resistance.

- Outstanding heat transfer.

- Extremely low pressure drop.

- Space-saving arrangement by installing in the horizontal or vertical position.

- Simple replacement of the inner tubes for repair and cleaning owing to a construction designed to permit easy servicing.

The standard range includes shell and tube heat exchangers in various sizes with exchange areas ranging from 2.5 to 25 m2. The shell diameters are DN150, 200 and 300. The standard design has a glass shell, glass tubes, PTFE end plates and baffles and either glass or stainless steel end covers. The tube bank is made up of single tubes sealed individually into two tube plates.

Damaged tubes can be either blanked off or replaced on site. The operating ranges (pressure and temperature) for the various types are as follows :-

Operating Ranges

- Maximum operating temperature (Shell side and tube side) : 150 deg C.

- Maximum temperature difference between the shell side and tube side process fluids: 130 K.

- Maximum operating gauge pressure and maximum pressure difference.

| DN | Exchange Area | Maximum Allowable Pressure (bar gauge) | ||

|---|---|---|---|---|

| (m2) | Shell (all types) | Tube Side Metal | Glass | |

| 150 | 2.5-5 | 2 | 3 | 2 |

| 200 | 5-10 | 1 | 3 | 1 |

| 300 | To 16 20 25 |

1 | 3 2.8 2.6 |

1 |

The particular advantage of the shell and tube heat exchanger lies in the high heat transfer coefficients. The following values can be used for approximate sizing:

- Liquid-Liquid exchange: k = 250 – 400 W/m2 K

- Condensation: k = 500 – 700 W/m2 K